Hydraulic

Fineblanking press FB one

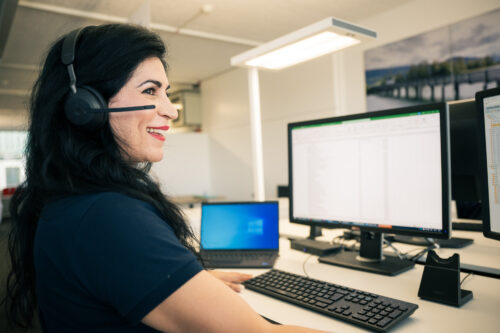

The FB one series takes fineblanking technology to a new level. Using our hydraulic fineblanking press for forces from 4,000 kN to 11,000 kN enables high flexibility and cost-effectiveness in the production of demanding components with high performance.

FB one

Machine highlights

≤ 50% less energy consumption

The innovative drive concept consumes less energy without loss of performance. Thus, the FB one achieves higher energy efficiency.

Resource-efficient

The two-level press concept does not require a foundation pit. This allows a simplified setup at the production site and permits flexible and adaptable layout planning.

≤ 40% reduction in the amount of oil

The new direct drive concept enables operation with up to 40 percent less oil content in the hydraulic tank and lower air content in the oil. This leads to longer replacement intervals.

Energy-saving waste separation

For energy-saving and process-optimized cutting of the punching grid, the waste separator module can be optimally adjusted to the punching grid. Additional pistons enable energy-saving cutting of the full strip cross-section.

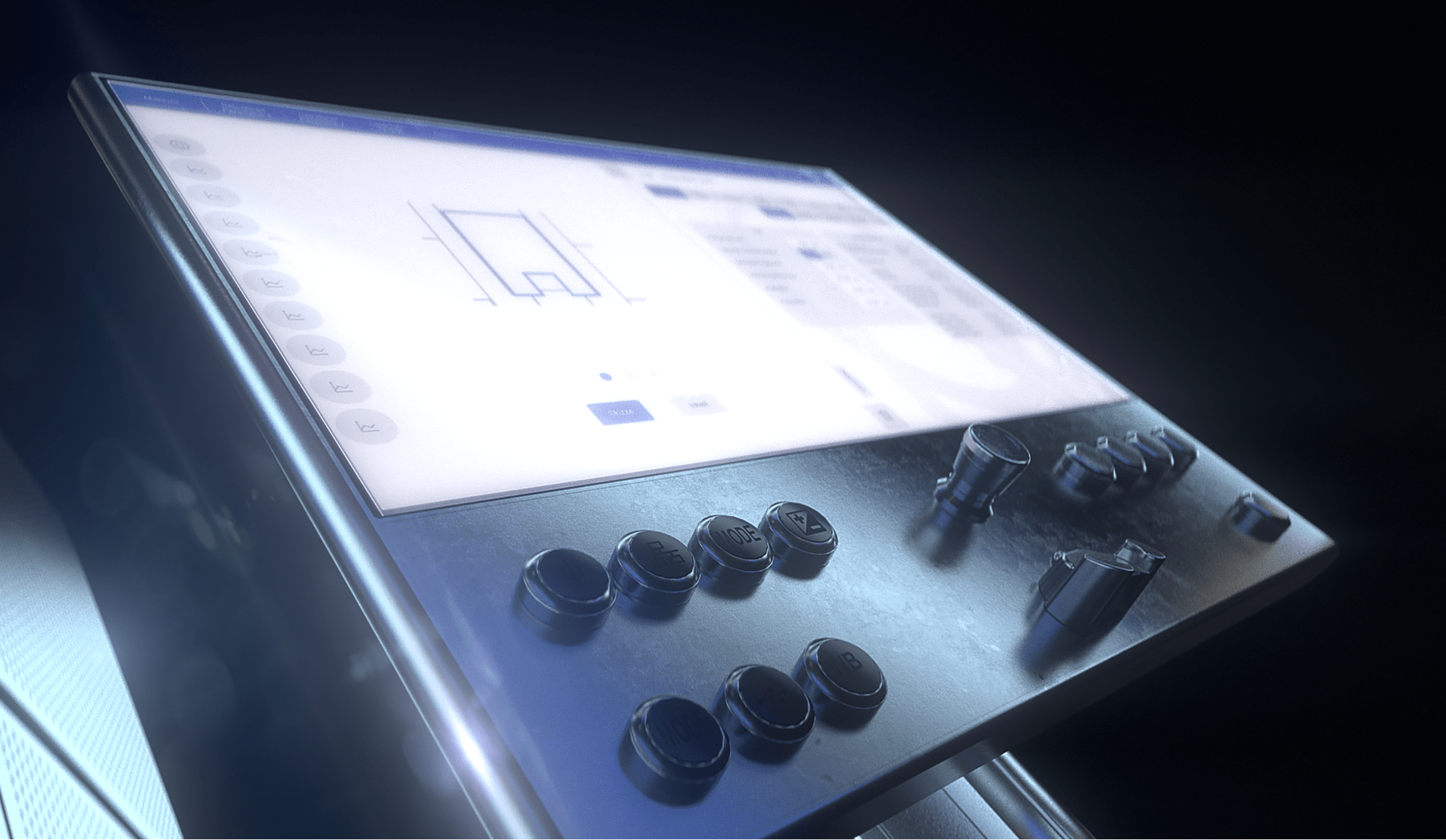

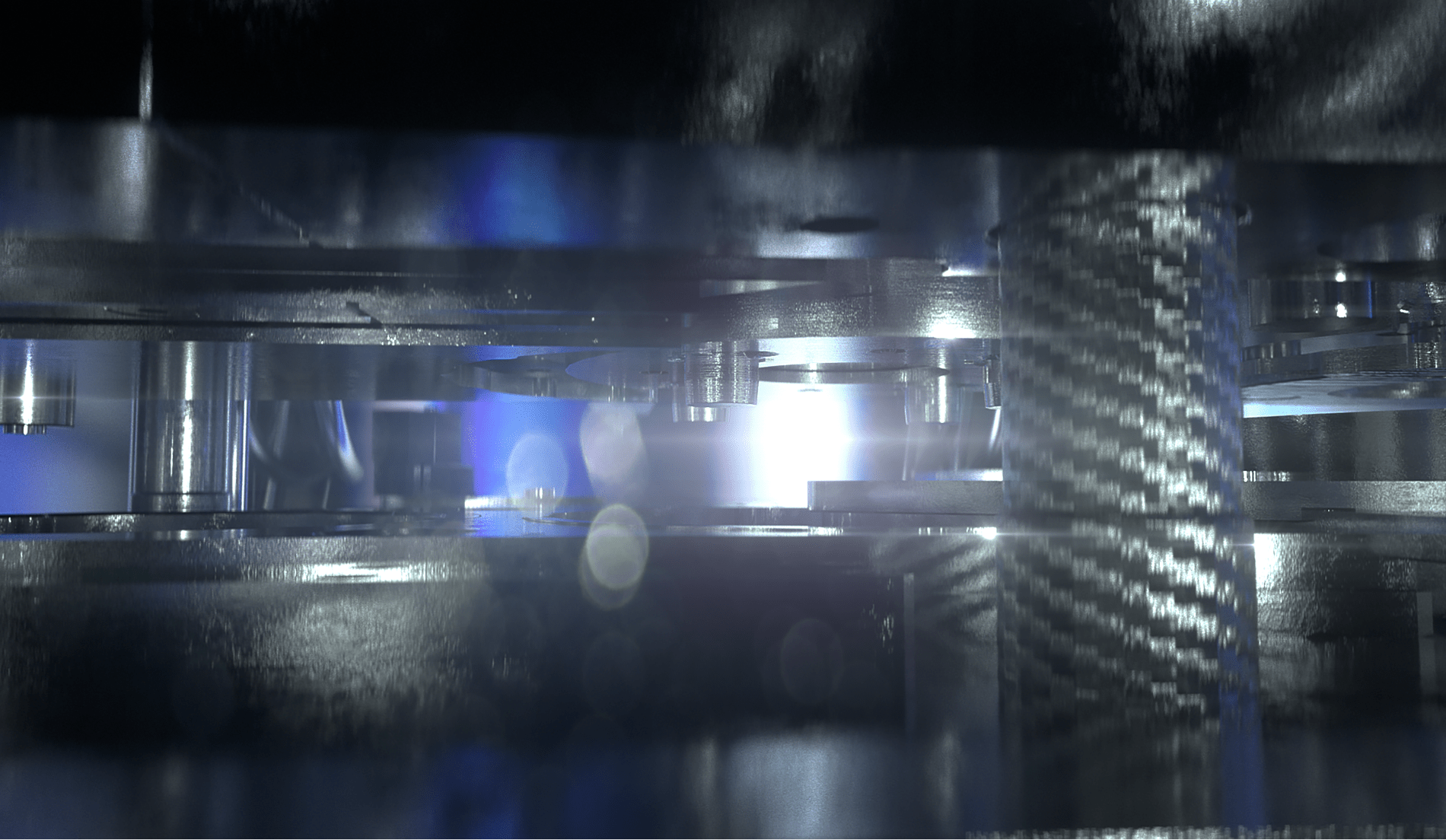

Efficient direct-drive technology

The hydraulic direct drive of the ram consumes significantly less energy and requires less oil. Thanks to the shorter switching times of the hydraulic components, higher stroke rates can be achieved with the best process reliability.

Next-level

fineblanking.

With the FB one, fineblanking technology reaches a new performance class. The consistent further development of the hydraulics, the design, the intuitive system control and the digital networking makes fineblanking more energy-efficient, more powerful, more precise and more flexible. This leads to greater economic efficiency.

Technical specifications

Total Force (kN)

Max. Plunger Stroke (mm)

Strokes/min.

Max. Material Width (mm)

Max. Material Thickness (mm)

Top Clamping Surface (mm)

Bottom Clamping Surface (mm)

Total Force (kN)

Max. Plunger Stroke (mm)

Strokes/min.

Max. Material Width (mm)

Max. Material Thickness (mm)

Top Clamping Surface (mm)

Bottom Clamping Surface (mm)

FB one 4500

4500

100

85

450

16

760x790

760x790

Total Force (kN)

Max. Plunger Stroke (mm)

Strokes/min.

Max. Material Width (mm)

Max. Material Thickness (mm)

Top Clamping Surface (mm)

Bottom Clamping Surface (mm)

FB one 7000

7000

100

85

450

16

760x790

760x790

Total Force (kN)

Max. Plunger Stroke (mm)

Strokes/min.

Max. Material Width (mm)

Max. Material Thickness (mm)

Top Clamping Surface (mm)

Bottom Clamping Surface (mm)

FB one 8800

8800

130

70

450

16

960x960

960x960

Total Force (kN)

Max. Plunger Stroke (mm)

Strokes/min.

Max. Material Width (mm)

Max. Material Thickness (mm)

Top Clamping Surface (mm)

Bottom Clamping Surface (mm)

FB one 11000

11000

130

60

450

16

960x960

960x960