Strong concepts.

Tool -

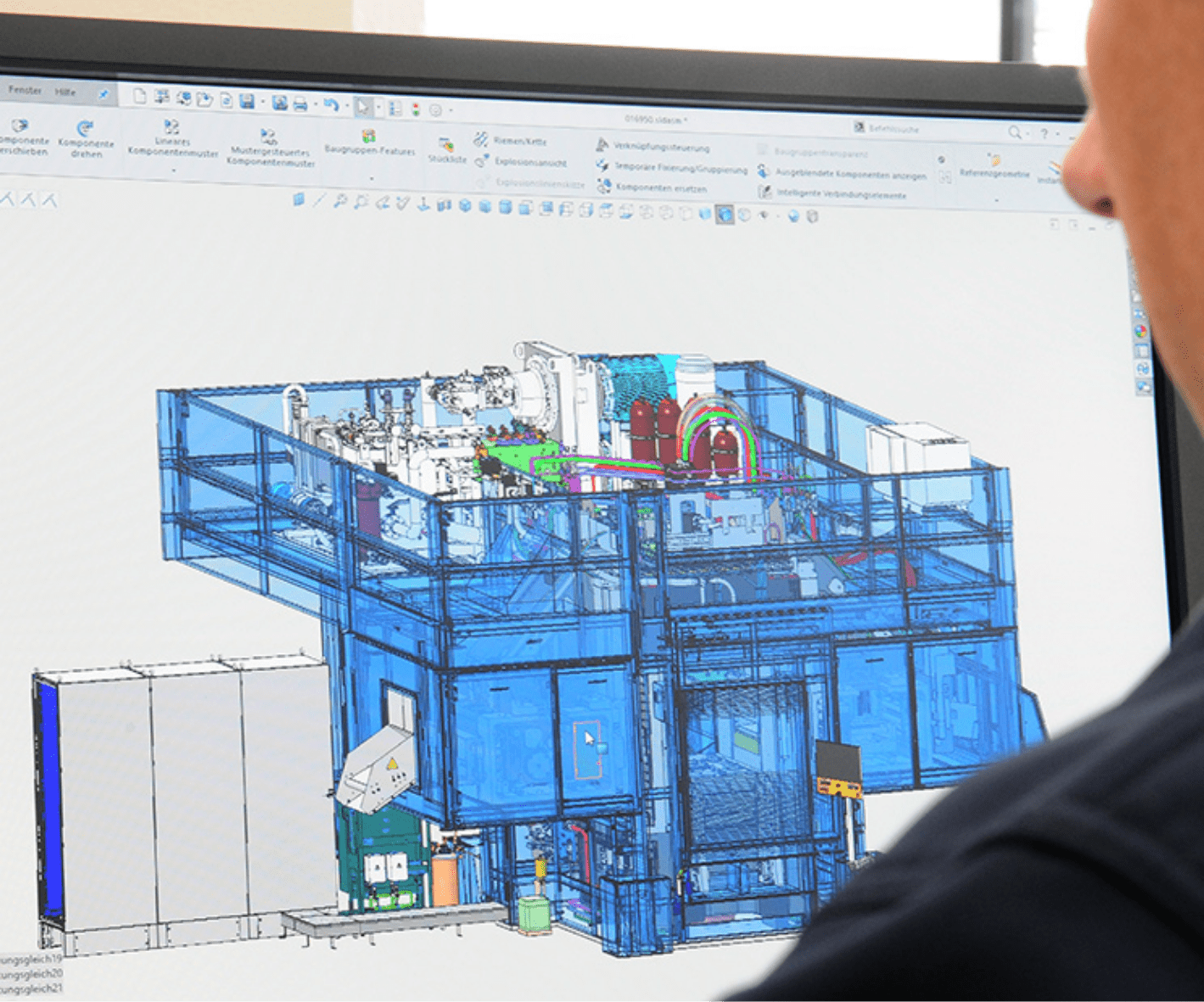

Engineering.

We develop tools for the highest performance. Along with analysis, concepts, designs, our specialists will support you in finding the perfect solution.

- Plannable unit costs

- 'Strip optimiser' for best-possible use of materials

- Knowledge base for efficient problem-solving

- Concept studies

- Consulting