The renowned Fraunhofer Institute for Machine Tools and Forming Technology IWU operates the “Referenzfrabik.H2” in Chemnitz, Germany, to enhance the competitiveness of hydrogen systems and actively advance the energy transition – this in addition to the developments in production technologies for hydrogen drives.

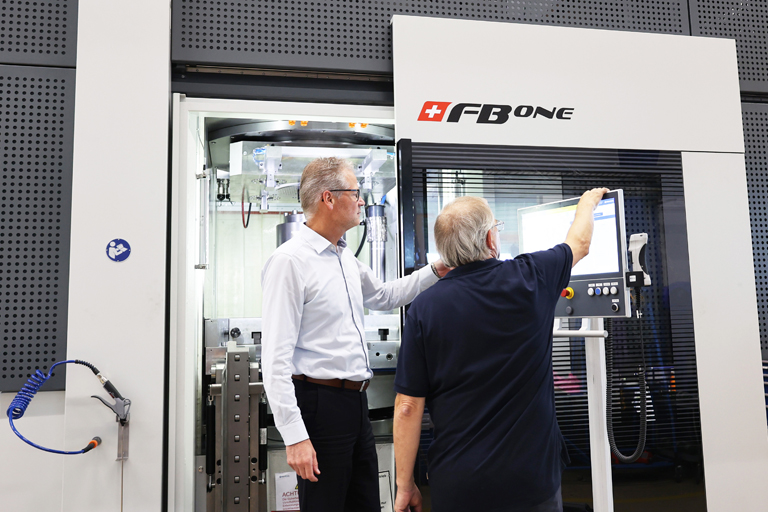

The institute is now using the FB one fineblanking press from Qcision for the series production of high-precision metallic bipolar plates for fuel cells and electrolyzers.

Qcision (formerly Feintool Technologie AG) and the Fraunhofer Institute IWU have a longstanding partnership. “We have worked together on machine development multiple times in the past,” explains Prof. Dr. Verena Kräusel, Head of Business Unit Forming Technology at the Fraunhofer IWU in Chemnitz. “The goal of expanding our collaboration with the FB one fineblanking press is to advance the series production of high-precision metallic bipolar plates. We aim to leverage Qcision's experience in bipolar plate production and fineblanking technology.”

Markus Schaltegger, CEO of Qcision, sees the collaboration as a flagship project. “With the FB one, Fraunhofer IWU has decided on a state-of-the-art fineblanking press that meets all relevant requirements for the successful series production of metallic bipolar plates. Rigidity, high precision, energy-efficient operation, and flexible usability are particularly important.”

Developing the energy systems of the future

The use of the FB one fineblanking press in the Referenzfrabik.H2 is part of a development partnership. Both the Fraunhofer Institute IWU and Qcision firmly believe that hydrogen is a key component of the energy systems of the future. Electrolyzers store energy in the form of hydrogen, while fuel cells use it, for example, to power trucks in a climate-friendly way. These technologies rely on high-precision, finely structured bipolar plates, which can be produced economically and in large quantities using the FB one fineblanking press.