Servo-mechanical

fineblanking press XFT speed

With the XFT speed fineblanking presses, we combine the advantages of hydraulics, servo-technology and mechanics to give your production a competitive advantage. High stroke rates with minimal downtimes - the guarantee for success.

XFT speed

Machine highlights

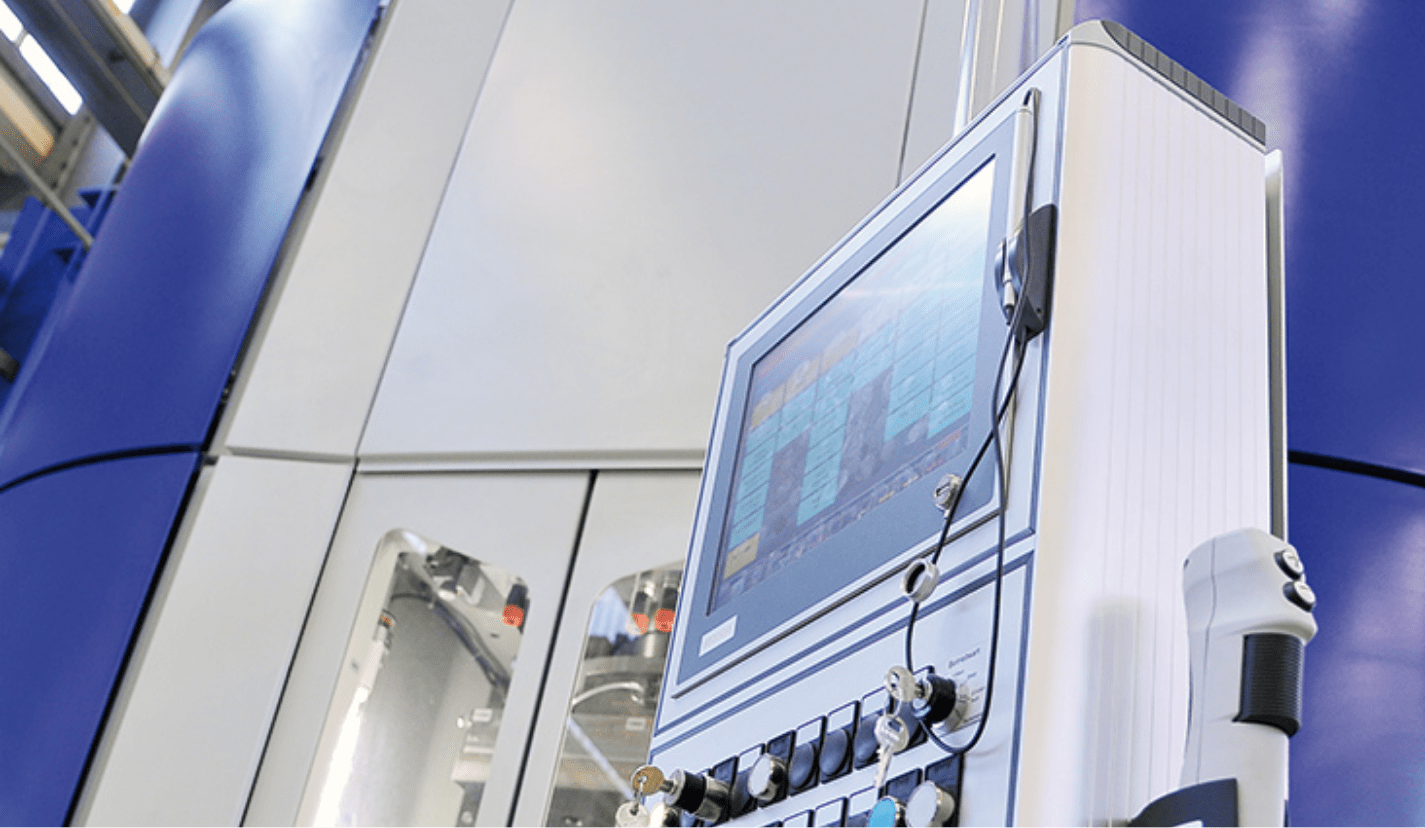

Unique: the servo direct drive.

The direct link between the servo-motor and the bolster plate results in high dynamics in the drive system. The press can stop fast if there is a fault, significantly shortening the stopping time. At the same time, the motors rotate more slowly and achieve energy savings.

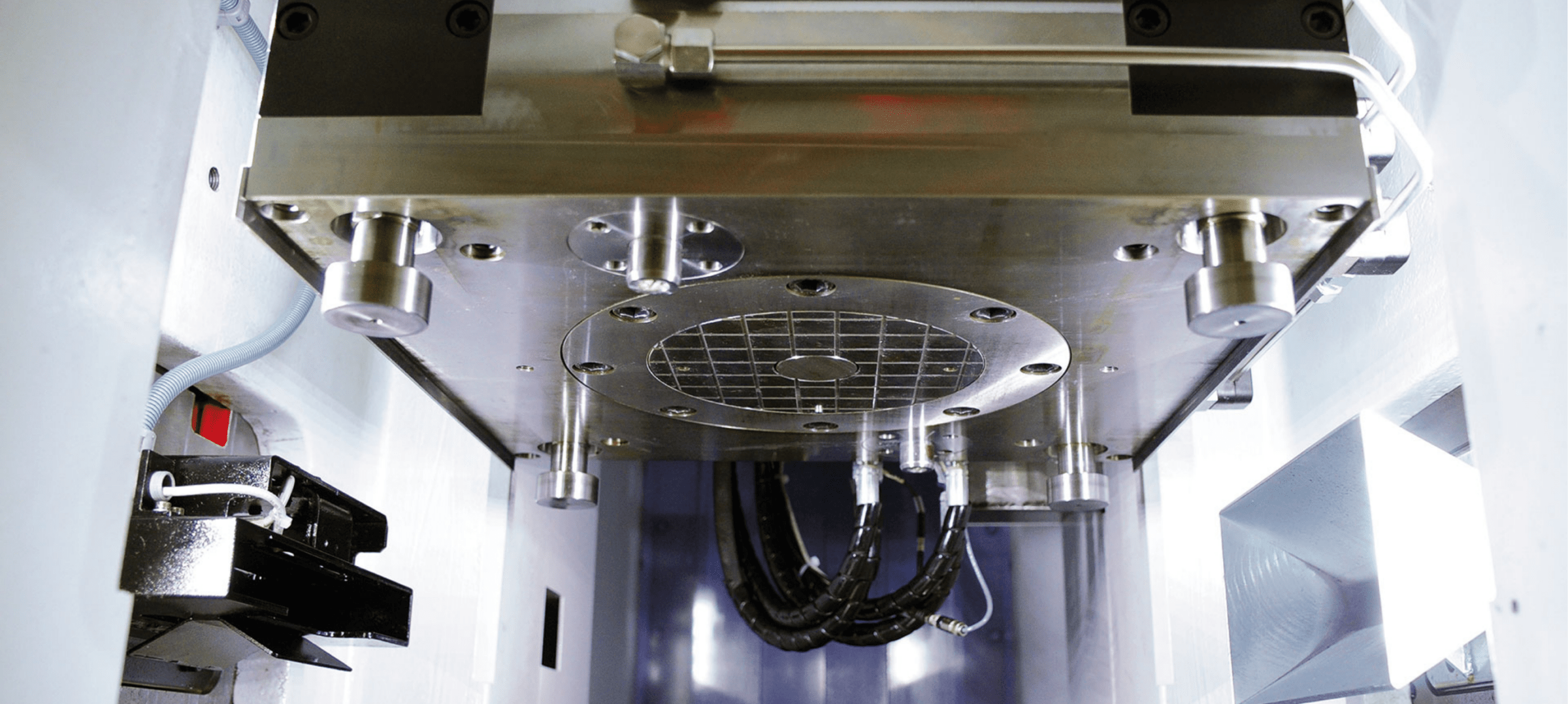

Sensitivity for process reliability.

The XFT speed series impresses with its sensitivity and fast reactions. The servo-mechanical drive interacts with the newly designed sensor plate and the new patented tool-installation space to significantly reduce the response time it takes to come to a standstill in case of faults or problems.

Flexible programming for productivity.

Both XFT speed press types allow simple and free programming of the movement sequences. Movements such as acceleration, braking, discharge or even intermediate stops can be freely defined. The result: You get the maximum out of a process while at the same time protecting the tools.

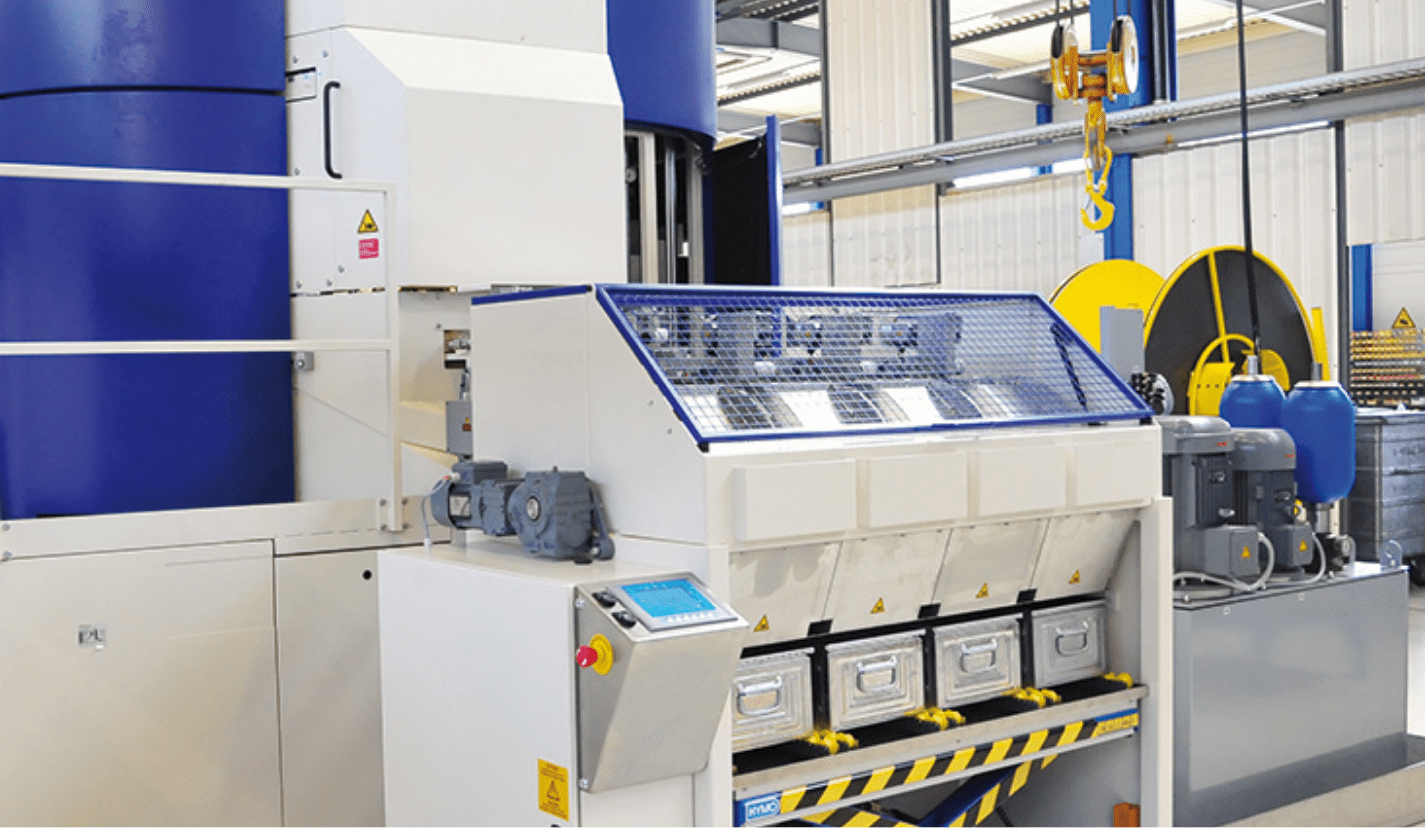

Tool changes made easy.

For energy-saving and process-optimised cutting of the punching grid, the waste separator module can be optimally adjusted to the punching grid. Additional pistons enable energy-saving cutting of the full strip cross-section.

Flexible

and efficient.

The XFT speed press series boasts short changeover times and high stroke rates. Its capacity, flexibility and process reliability offer our press series all the prerequisites to increase the performance of your production process.

Technical Specifications

Total force (kN)

Max. plunger stroke (mm)

Strokes/min

Max. width (mm)

Max. thickness (mm)

Top clamping surface (mm)

Bottom clamping surface (mm)

Total force (kN)

Max. plunger stroke (mm)

Strokes/min

Max. width (mm)

Max. thickness (mm)

Top clamping surface (mm)

Bottom clamping surface (mm)

XFT 1500 speed

1500

50

200

220

6

480x480

480x480

Total force (kN)

Max. plunger stroke (mm)

Strokes/min

Max. width (mm)

Max. thickness (mm)

Top clamping surface (mm)

Bottom clamping surface (mm)

XFT 2500 speed

2500

70

140

250

10

600x600

600x600